HIGHLIGHTS:

- Tough steel frame and reliable whole-welded body, created for heavy duty operation with high payloads;

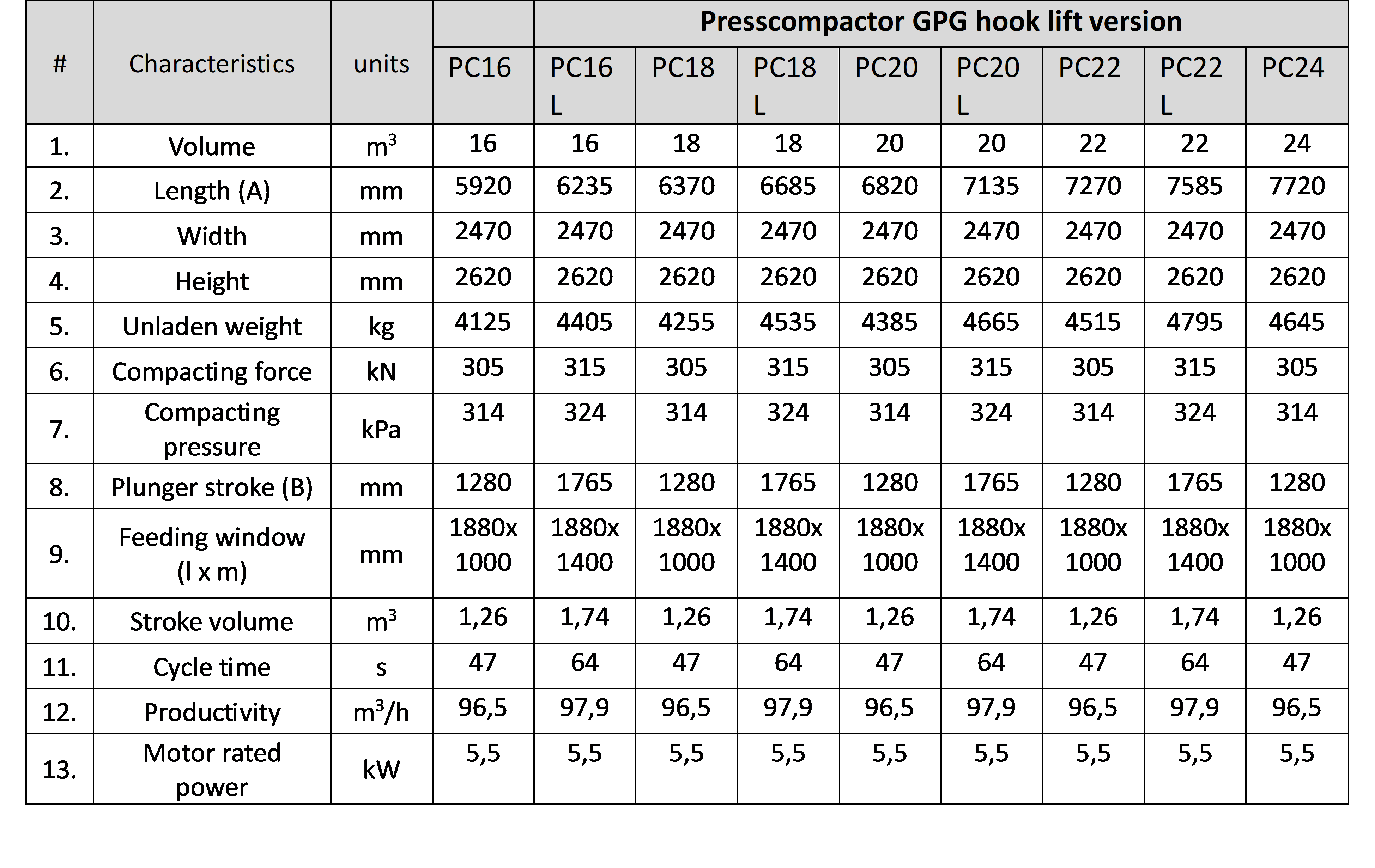

- High compacting capability, up to 6 times reduction of initial volume due to the high compacting pressure up to 324 kPa;

- Reliable, practice-proven press design with a minimum of wearable components;

- High-quality hydraulic unit with a large margin of safety;

- Expandable profile of container towards to emptying door ensures its easy emptying;

- Highly reliable low-voltage automatic and safety control fully meets all CE requirements;

- Simple, intuitive controls that don’t require essential training;

- High-quality polymer coating for high corrosion protection, long-term operation, and excellent appearance.

- High compacting capability, up to 6 times reduction of initial volume due to the high compacting pressure up to 324 kPa;

- Reliable, practice-proven press design with a minimum of wearable components;

- High-quality hydraulic unit with a large margin of safety;

- Expandable profile of container towards to emptying door ensures its easy emptying;

- Highly reliable low-voltage automatic and safety control fully meets all CE requirements;

- Simple, intuitive controls that don’t require essential training;

- High-quality polymer coating for high corrosion protection, long-term operation, and excellent appearance.