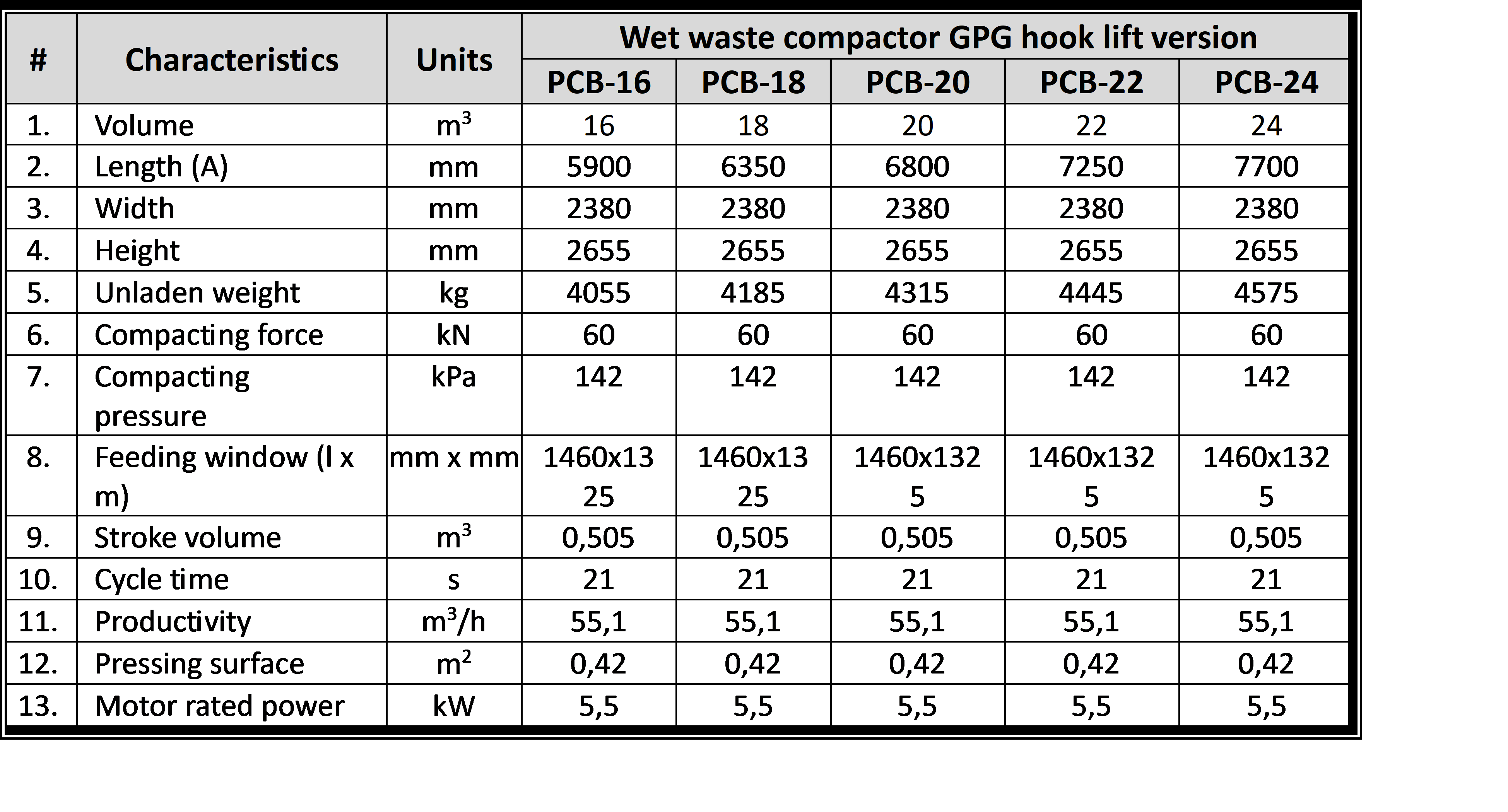

MAIN CHARACTERISTICS OF THE WET WASTE COMPACTOR GPG PCB:

- Large range of available container volumes, manufactured serially (16,18, 20, 22 and 24 cbm) or upon request

(6 - 16 cubic meters);

- Two versions of hoppers to meet customers` requests, providing operation from the ground as well as from the

ramp;

- The possibility to choose between metal or polyamide front and rear rollers, or a combination of both,

allows the wet waste compactors to be used on all types of grounds;

- Ozonizer, installed optionally, for elimination of unpleasant odor from inside of storage container allows

to use waste compactors even in dense urban areas;

- The design of bio-compactors with integrated lifter for garbage bins of EN840-2 and -3 standards with

capacities from 500 to 1300 liters makes it a convenient tool in a chain of collection of household and

similar waste;

- Several locking options for a discharge door, as well as the possibility to install additional bottom and

side locks, ensures convenient operation even in the most specific conditions;

- Full or partial sealing of a discharge door, depends on customer requirements;

- Installation of an optional rear drain valve, in addition to the standard front one, for complete removal of

filtrate, regardless of the surface incline;

- The controller, which provides automatic pressing mode for 3 cycles with the pendulum stopping in the

closure zone, better keeps the waste in the volume of the storage container;

- Additional control panel mounted on the hopper door or wired version of the control panel for remote

operation of the waste compactor from a ramp;

- Filling control of the storage container, automatic detection of 75% and 100% fullness; Individual key to

prevent unauthorized operation of the compactor;

- The use of PLC controller in the control system provides the possibility of flexible and quick readjustment

of the waste compactor working cycle parameters for specific customer’s tasks;

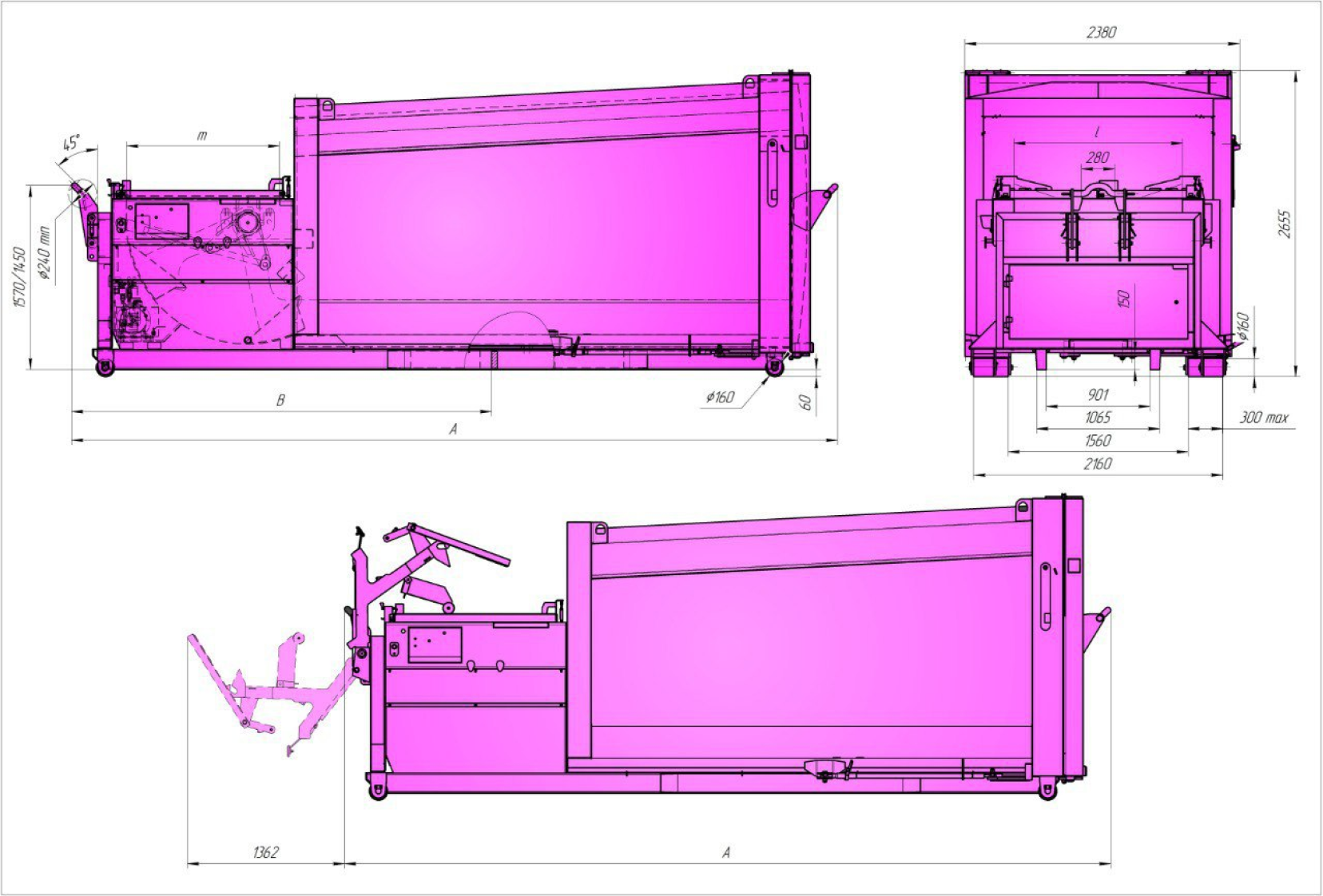

- Foldable front hook for easy operation of the press container and a rear hook that allows the container to

be manipulated on site;

- Full compliance with DIN 30722 for the manufacture and operation of containers with hook trucks and the

ability to adapt the height of the hitch bracket to different hook trucks.